Smoke from the Burning or Decomposition of Plastics | ASTM D2843 Compliance ASTM D2843

Smoke from the Burning or Decomposition of Plastics | ASTM D2843 Compliance ASTM D2843

Smoke from the Burning or Decomposition of Plastics | ASTM D2843

Compliance

ASTM D2843

Smoke Density Tester (ASTM D2843)

The Smoke Density Tester, as per ASTM D2843 – Standard Test Method for Density of Smoke from the Burning or Decomposition of Plastics, is designed to measure and observe the relative smoke obscuration produced by burning or decomposing plastics under controlled laboratory conditions. This test provides two key indexes:

- Maximum Smoke Produced

Smoke-Density Rating

Summary of ASTM D2843 Test

- Specimen Size: 25 mm × 25 mm × 6 mm

- The specimen is placed on a specimen holder inside a sealed chamber (300 mm × 300 mm × 790 mm).

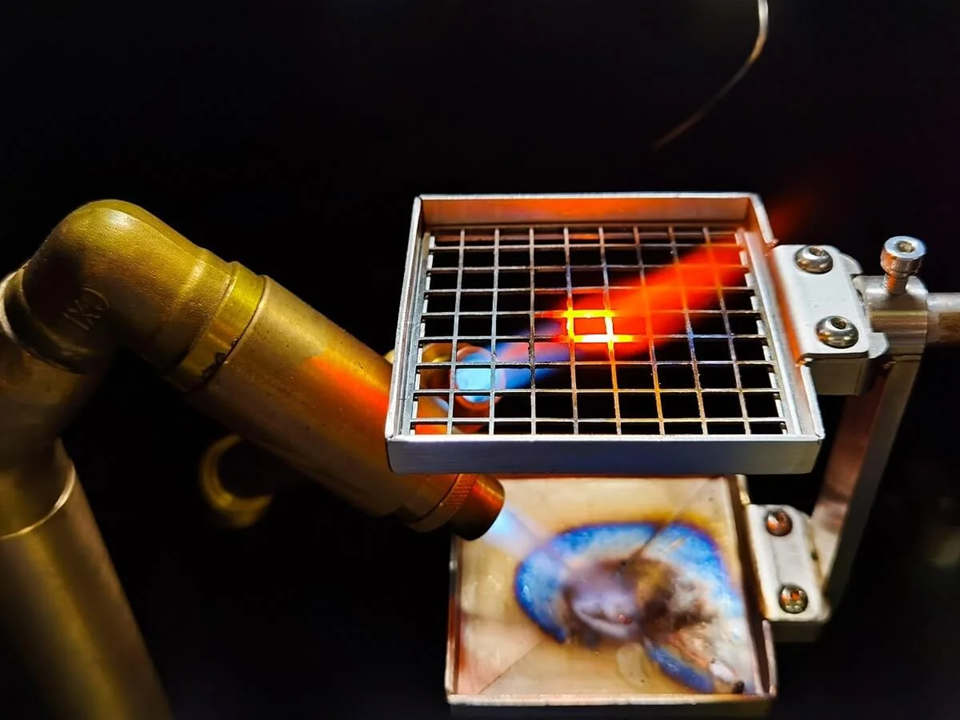

- A propane burner flame is applied to the specimen. If molten material drops occur, an auxiliary burner flame may be applied.

- Burning occurs in the smoke chamber, which is fitted with a light measurement system and an EXIT sign on the rear wall.

- The test runs for 4 minutes.

- Light absorption (transmittance) vs. time is recorded, and the visibility of the EXIT sign is observed.

- The smoke-density rating is determined from light-obscuration data.

Exit Sign Smoke Chamber Apparatus

- Stainless Steel Chamber: 300 mm × 300 mm × 790 mm.

- Internal Surface: Coated with Teflon paint to resist corrosion and reduce reflection.

- EXIT Sign: Mounted on the back wall, red letters on white background, visible through a front observation window for qualitative observation.

- Light Source: Incandescent lamp.

- Photodetector: Silicon photodiode, cosine-corrected, fitted with optical filters to block UV and IR light (mimicking human eye sensitivity).

- Exhaust Fan: Removes combustion gases after test completion.

- Main Burner: Propane, supplied at 276 kPa.

- Auxiliary Burner: For molten drops, propane at 138 kPa.

- Data Acquisition: Records light transmittance at 15-second intervals.

Software & Data Handling

- English Operation Software with:

- Calibration function for the light system.

- Standard ASTM D2843 test sequence.

- Data recording and reporting functions.

- Output: Generates both raw data and formatted reports as required by ASTM D2843.