Lateral Flame Spread Test ISO 5658-2, IMO FTP Code

Lateral Flame Spread Test ISO 5658-2, IMO FTP Code

ISO 5658-2: LIFT (Lateral Flame Spread Test) / IMO Spread of Flame Apparatus

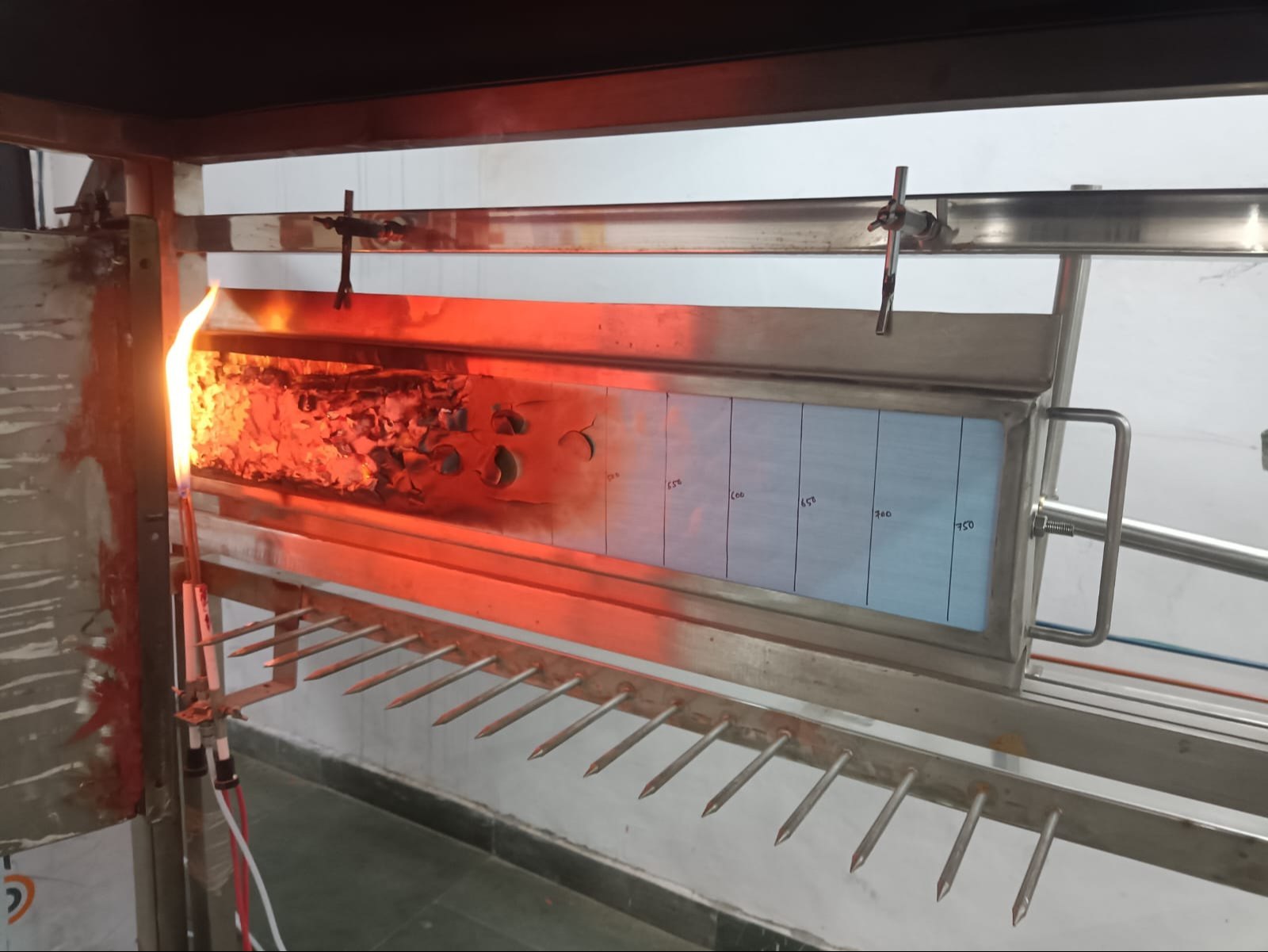

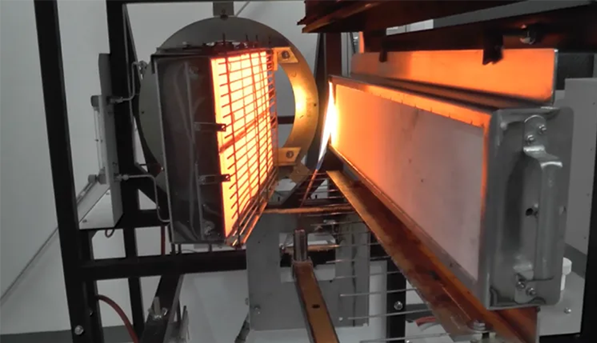

The LIFT / IMO Spread of Flame Apparatus, in accordance with ISO 5658-2, provides a standardized method for measuring the lateral spread of flame along the surface of vertically mounted test specimens exposed to a controlled gas-fired radiant heat panel.

This method is widely used to evaluate the reaction to fire performance of flat materials, composites, or assemblies in building, railway, and marine applications. Certain profiled products may also be tested under specified mounting conditions.

FlareTest is a reputed Manufacturer of Lateral Flame Spread Test ISO 5658-2, an advanced testing system designed to measure the flame spread properties of materials under controlled heat radiation. This instrument accurately evaluates the lateral flame spread rate across a specimen’s surface when exposed to radiant heat, complying with the ISO 5658-2 standard. Built for high precision, stability, and repeatability, it is ideal for fire testing laboratories, research institutes, and quality control departments. Featuring intelligent controls, durable construction, and precision sensors, the FlareTest Lateral Flame Spread Test ISO 5658-2 system ensures consistent performance, safety, and ISO-compliant fire testing accuracy.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Andhra Pradesh

FlareTest is a leading Lateral Flame Spread Test ISO 5658-2 Manufacturer in Andhra Pradesh, offering top-quality fire testing instruments engineered for accuracy and reliability. Our systems measure the lateral flame propagation of materials in compliance with ISO 5658-2 standards. Built with robust components, precise sensors, and automated control systems, our equipment ensures dependable and repeatable testing performance. Across Andhra Pradesh, FlareTest serves laboratories, industrial testing units, and research organizations with world-class, ISO-certified flame spread testing equipment.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Arunachal Pradesh

FlareTest is a trusted Lateral Flame Spread Test ISO 5658-2 Manufacturer in Arunachal Pradesh, providing advanced instruments to evaluate flame spread characteristics of materials. Our equipment follows ISO 5658-2 test procedures, ensuring accurate and consistent measurements. With precision engineering, reliable operation, and durable construction, our test systems are ideal for laboratories, research facilities, and industries across Arunachal Pradesh. FlareTest guarantees excellent performance, ISO compliance, and long-lasting quality in all our flame spread testing solutions.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Chhattisgarh

FlareTest stands as a reputed Lateral Flame Spread Test ISO 5658-2 Manufacturer in Chhattisgarh, offering precision-built systems for evaluating material flame propagation. Designed according to ISO 5658-2 standards, our instruments provide reliable results with accurate control of radiant heat and air flow. These systems are ideal for industrial and research laboratories performing detailed flame spread studies. Across Chhattisgarh, FlareTest delivers durable, high-performance fire testing equipment with assured quality and technical excellence.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Himachal Pradesh

FlareTest is a renowned Lateral Flame Spread Test ISO 5658-2 Manufacturer in Himachal Pradesh, specializing in the production of fire testing instruments built for precision and reliability. Our systems conform to ISO 5658-2 standards and are designed to evaluate the rate and extent of flame spread over materials under radiant heat exposure. With high-end sensors and advanced controls, they ensure accurate, repeatable testing. FlareTest provides high-quality, ISO-certified equipment to testing facilities and research centers across Himachal Pradesh.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Madhya Pradesh

FlareTest is a reputed Lateral Flame Spread Test ISO 5658-2 Manufacturer in Madhya Pradesh, producing advanced fire testing systems that analyze material flame spread properties. Our equipment, designed as per ISO 5658-2 guidelines, delivers reliable and consistent results through precision engineering and stable operation. Ideal for research, industrial, and quality control applications, these instruments ensure compliance with international standards. Across Madhya Pradesh, FlareTest is known for manufacturing durable, accurate, and efficient flame spread testing equipment.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Maharashtra

FlareTest is a prominent Lateral Flame Spread Test ISO 5658-2 Manufacturer in Maharashtra, offering state-of-the-art fire testing systems that comply with ISO standards. Our instruments are designed to evaluate the lateral spread of flames across materials when exposed to radiant heat, providing precise and repeatable results. With durable construction, digital controls, and accurate sensors, they ensure superior performance and safety. FlareTest serves laboratories and industries across Maharashtra with reliable and ISO 5658-2 compliant flame spread testing equipment.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Haryana

FlareTest is a trusted Lateral Flame Spread Test ISO 5658-2 Manufacturer in Haryana, offering premium-quality instruments for assessing flame spread behavior. Our systems, built in accordance with ISO 5658-2 standards, deliver precise and repeatable test results. Designed for both industrial and research laboratories, they feature robust components and advanced control systems for accurate heat radiation and airflow management. FlareTest provides dependable fire testing solutions across Haryana with assured performance and compliance.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Punjab

FlareTest is a reputed Lateral Flame Spread Test ISO 5658-2 Manufacturer in Punjab, manufacturing high-performance fire testing instruments used for determining flame spread rates on material surfaces. Our equipment fully meets ISO 5658-2 requirements, ensuring reliability and consistency in every test. Built with advanced heating elements, safety features, and precision sensors, it delivers unmatched accuracy. FlareTest supplies top-quality flame spread testing systems across Punjab, trusted by laboratories and research institutes.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Uttar Pradesh

FlareTest is a recognized Lateral Flame Spread Test ISO 5658-2 Manufacturer in Uttar Pradesh, delivering high-accuracy fire testing instruments for material evaluation. Our systems follow ISO 5658-2 methodologies to measure lateral flame propagation under radiant heat. Engineered for precision and efficiency, they provide consistent, dependable results across a wide range of materials. Across Uttar Pradesh, FlareTest serves research centers, universities, and industries with world-class, ISO-compliant flame spread testing equipment.

Lateral Flame Spread Test ISO 5658-2 Manufacturer in Uttarakhand

FlareTest is a leading Lateral Flame Spread Test ISO 5658-2 Manufacturer in Uttarakhand, offering advanced and durable systems for evaluating flame spread performance. Our instruments comply with ISO 5658-2 standards and provide accurate data on material behavior under radiant heat. Built with precision sensors, robust construction, and easy-to-use controls, they ensure stable and repeatable results. FlareTest serves clients throughout Uttarakhand with dependable, ISO-certified fire testing instruments known for quality and reliability.

Apparatus Construction

- Frame Structure

- Fabricated from 40 × 40 mm square steel tubing

- Coated with white anti-corrosion paint for durability

- Radiant Heat Panel

- Dimensions: 480 × 280 mm

- Porous ceramic refractory panel mounted in a stainless steel plenum chamber

- Provides stable, luminous flame-free radiant heat source

- Gas Supply & Mixing System

- Propane gas and air supplied through a Venturi mixer

- Propane mass flow controller (±1% accuracy) for combustion gas control

- Blower with inverter for adjustable clean air supply

- Non-return valve and pressure regulator for safety in gas line

- Electrical shut-off valve for automatic gas cut-off in case of radiant panel failure

- Spark ignitor for reliable ignition

- Ceramic pilot flame burner (twin-bore Ø1.5 mm, 200 mm length)

- Specimen Holder

- Constructed from stainless steel for durability and non-combustibility

Measurement & Calibration System

- Heat Flux Meter

- Schmidt-Boelter type

- Measurement range: 0–50 kW/m²

- Equipped with integrated water-cooling unit (no external water supply required, no maintenance)

- Calibration Gas Flow Control

- Methane gas mass flow controller (±1% accuracy) for system calibration

- Calibration Materials

- Non-combustible calibration board (density: 950 ± 100 kg/m³)

- Non-combustible dummy specimen (density: 950 ± 100 kg/m³)

Control & Data Acquisition

- Control System

- Industrial 15" touch screen computer for full test monitoring and operation

- Integrated standard operation software including:

- Heat flux calibration

- Methane gas calibration

- Standard test procedure management

Automated test report generation