EN 16989 Fire behaviour test for a complete seat EN 16989, EN 45545-2

EN 16989 Fire behaviour test for a complete seat EN 16989, EN 45545-2

EN 16989 Fire behaviour test for a complete seat

Compliance

EN 16989, EN 45545-2

Calorimetry System for Complete Railway Seats

As per EN 16989 and EN 45545-2

Scope

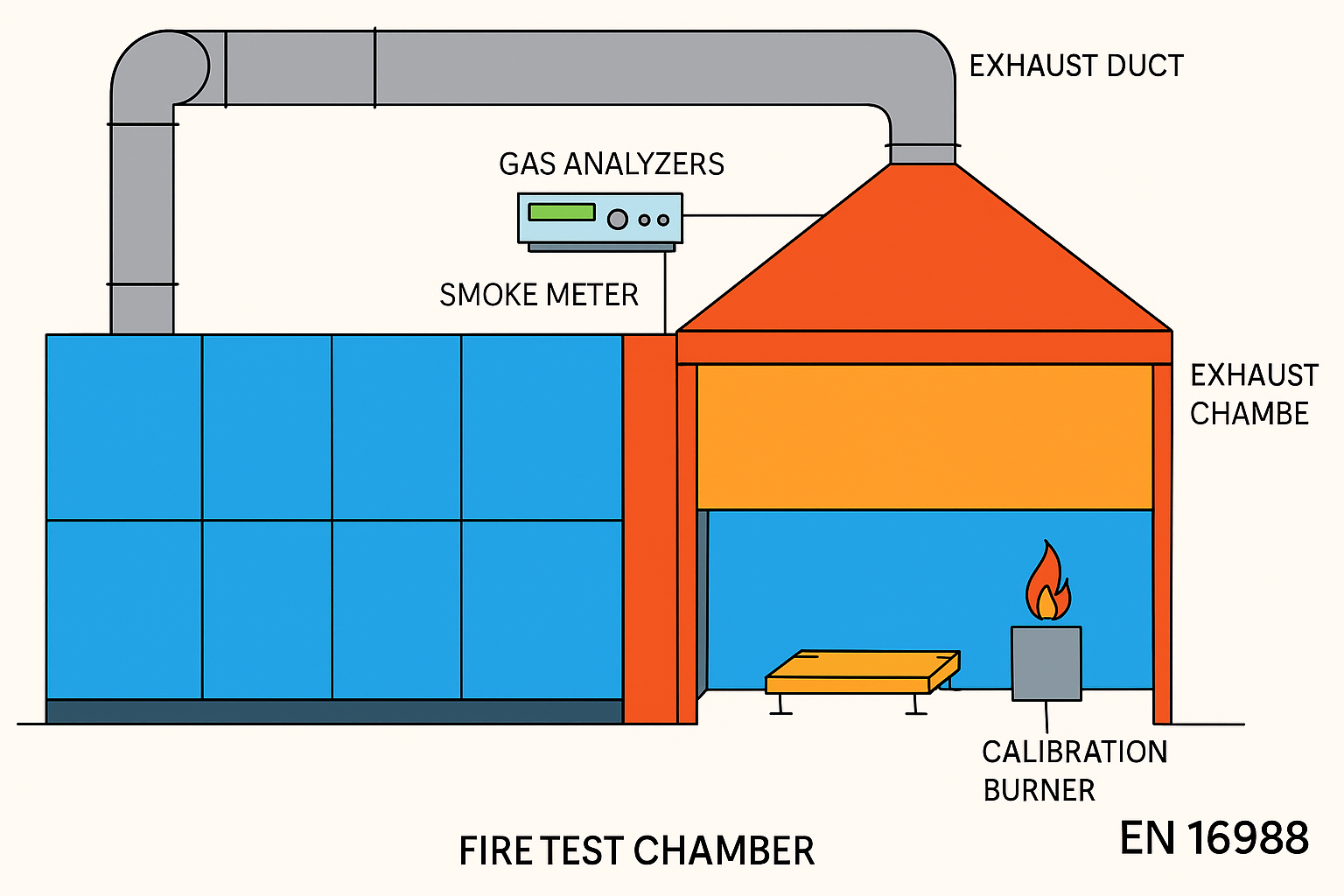

The system provides a means of determining the burning behaviour of a complete railway seat design under standardized conditions. It also evaluates the seat’s potential for vandalization, in compliance with EN 16989.

Test seats are exposed to a 15 kW propane-fueled ignition source under a well-ventilated exhaust hood.

Measurements include:

- Heat Release Rate (HRR)

- Maximum Average Heat Release (MARHE)

- Total Smoke Production (TSP)

- Flame Height

System Components

1. Calorimetry Measurement System

- Test room, collection hood, ducts, and instrumented duct.

- Mass flow controllers for both test burner and calibration burner.

- Data acquisition & Windows-based software.

- Gas concentration analysis system.

2. Instrumented Duct Assembly

- Pressure Probe: ISO 9705 bi-directional probe, stainless steel, connected via Teflon tubing.

- Pressure Transmitter: Range 0–250 Pa, accuracy ±2.5 Pa, T90 < 1s.

- Thermocouples: 3 × K-type, 0.5 mm, EN 60584 compliant, armoured insulated.

- Sampling Probe: Stainless steel, quick-disassembly, easy cleaning.

3. Optical Smoke Measurement (Light Attenuation System)

- Light Source: Incandescent lamp, colour temperature (2900 ± 100)K, DC power supply with ±0.5% stability.

- Lens System: Produces ≥20 mm parallel beam; aperture ratio d/f < 0.04.

- Detector: Imported silicon photodiode, CIE V(λ) response, linear stability 0.1%, accuracy ±5%.

- Response Time: T90 ≤ 3s.

4. Ignition & Burner Control

- Test Burner: Propane, mass flow controller range 0–450 mg/s, accuracy ±2%, response 0.1s.

- Stability: Controlled via software, 324 ± 5 mg/s.

- Ignition: Integrated device with automatic timing & extinguishing.

- Calibration Burner:

- ISO 9705 flame calibration burner.

- Alicat MFC, range 0–7 g/s, accuracy ±2%, response 0.1s.

- Output up to 300 kW, step calibration function.

- Pilot flame ignition, remote controlled, safe and reliable.

5. Gas Concentration Analysis

- Filtration System:

- Glass fibre cotton coarse filter

- Parker filter, precision 2 μm

- PTFE membrane, precision 0.5 μm

-

- All filters quick-replaceable.

- Cold Trap: Compressor type, cooling capacity 320 kJ/h, dew point stability ±0.1°C, self-starting, auto water discharge.

- Sampling Pump: Vacuum type, 16 L/min, continuous +50 kPa, low noise, low vibration.

- Flowmeter: Range 0–1 L/min, ensures stable gas flow to analyzer.

- Analyzers:

- O? (Paramagnetic), 0–25%, accuracy ±0.01%

- CO? (NDIR), 0–10%, accuracy ±0.01%

6. Data Acquisition & Control Software

- DAQ System (Advantech module):

- O?, CO? accuracy: 100 × 10?? (0.01%)

- Temperature accuracy: ±0.5°C

- Other instruments: ±0.1% FS

- Time accuracy: ±0.1s

- Software Features:

- Sensor calibration

- System step calibration

- Standardized test sequences

- Real-time data recording and visualization

- Automatic reporting & export

Compliance

- EN 16989: Railway seat calorimetry fire test method

- EN 45545-2: Railway fire safety standard

- ISO 9705: Full-scale room fire test reference for calibration

EN 60584: K-type thermocouple compliance