Cone Calorimetter ISO 5660-1, ASTM E1354

Cone Calorimetter ISO 5660-1, ASTM E1354

Cone Calorimeter

Compliance

ISO 5660, ASTM E1354, BS 476-15, ASTM E1474; ASTM E1740; ASTM F1550; ASTM D6113; CAN ULC 135.

The cone calorimeter is a critical instrument used in fire testing and research. It facilitates the miniaturization of fire tests, providing a robust dataset with excellent repeatability.

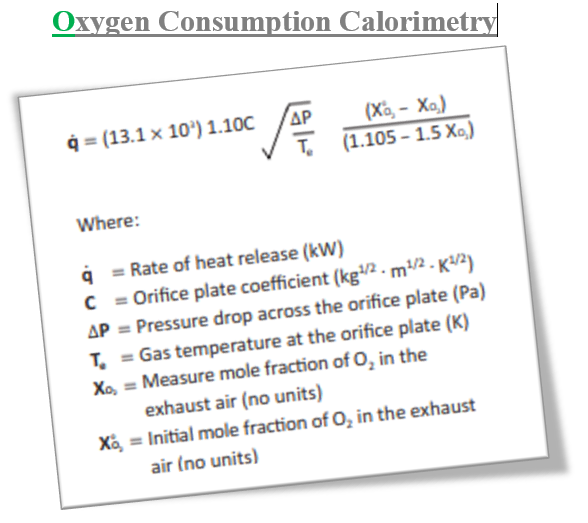

The cone calorimeter provides a method for assessing the rate of heat release and the rate of smoke production for specimens exposed in a horizontal orientation to controlled levels of irradiance, in the presence of an external igniter. The rate of heat release is determined by measuring the oxygen consumption, which is derived from the oxygen concentration and the flow rate of the combustion gas. The rate of smoke production is calculated from the attenuation of a laser light beam by the combustion gas.

The rate of heat release and smoke obscuration are recorded for the entire duration of the test, irrespective of whether the specimen is in the flaming or non-flaming phase.

The following data shall be reported from the cone calorimeter test:

- Rate of heat release, in kW/m2

- Total heat release, in MJ/m2

- Rate of smoke production, in m2/s

- Total smoke production, in m2

- Mass loss rate, in g/s

- Time to sustained flaming and time of extinguishment, in seconds

- Heat flux, in kW/m2

- Exhaust duct flow rate, in L/s

- Test duration, in seconds

- C-factor, in 1/kg⋅m⋅K

FlareTest is a reputed Manufacturer of Cone Calorimeter ISO 5660-1, designed for accurate and reliable fire testing of materials according to global safety standards. Our advanced cone calorimeter system precisely measures heat release rate, ignition time, smoke generation, and combustion performance, providing vital data for research and industrial fire safety evaluations. Built with durable materials and precision engineering, it ensures stable performance and consistent results. FlareTest’s Cone Calorimeter ISO 5660-1 is ideal for laboratories, R&D facilities, and industrial testing centers that require precision, efficiency, and ISO-compliant fire analysis across India.

Cone Calorimeter ISO 5660-1 Manufacturer in Andhra Pradesh

FlareTest is a leading Cone Calorimeter ISO 5660-1 Manufacturer in Andhra Pradesh, offering world-class fire testing instruments designed for accurate and efficient combustion analysis. Our equipment conforms to ISO 5660-1 standards, ensuring precise measurements of heat release rate, ignition, and smoke production. Engineered with advanced sensors and robust materials, it provides reliable data and long-lasting performance. Serving research institutes, industries, and laboratories across Andhra Pradesh, FlareTest delivers durable and high-performance cone calorimeters that meet global fire safety testing needs.

Cone Calorimeter ISO 5660-1 Manufacturer in Arunachal Pradesh

FlareTest is a trusted Cone Calorimeter ISO 5660-1 Manufacturer in Arunachal Pradesh, offering superior-quality fire testing systems for material analysis. Our ISO 5660-1 compliant cone calorimeters provide accurate measurements of heat release, smoke generation, and ignition properties. Built with precision components and intelligent design, these instruments ensure repeatable and reliable performance. Widely used in educational institutions, industrial quality labs, and R&D centers across Arunachal Pradesh, FlareTest ensures durability, safety, and advanced fire testing capabilities in every product we manufacture.

Cone Calorimeter ISO 5660-1 Manufacturer in Chhattisgarh

FlareTest stands as a reputed Cone Calorimeter ISO 5660-1 Manufacturer in Chhattisgarh, specializing in high-precision fire testing instruments. Our cone calorimeters accurately evaluate the heat release rate, smoke density, and ignition characteristics of materials as per ISO standards. Engineered for stability and precision, our products are ideal for laboratories and industrial applications requiring dependable fire performance data. FlareTest serves clients across Chhattisgarh, ensuring timely delivery, robust build quality, and consistent accuracy for all fire testing requirements.

Cone Calorimeter ISO 5660-1 Manufacturer in Himachal Pradesh

FlareTest is a renowned Cone Calorimeter ISO 5660-1 Manufacturer in Himachal Pradesh, producing advanced fire testing equipment for research and industrial applications. Our cone calorimeters are designed for precise analysis of combustion and flammability under ISO 5660-1 conditions. Built using durable materials and high-sensitivity sensors, they offer excellent accuracy and operational efficiency. Trusted by laboratories and industries across Himachal Pradesh, FlareTest provides reliable and long-lasting instruments for critical fire testing procedures.

Cone Calorimeter ISO 5660-1 Manufacturer in Madhya Pradesh

FlareTest is a reputed Cone Calorimeter ISO 5660-1 Manufacturer in Madhya Pradesh, delivering cutting-edge fire testing instruments for material evaluation. Our cone calorimeter provides detailed analysis of heat release rate, ignition time, and smoke production following ISO 5660-1 standards. Designed for durability and easy operation, it ensures accurate and repeatable results for various materials. Used widely in R&D facilities and testing laboratories across Madhya Pradesh, FlareTest’s instruments are known for performance, reliability, and compliance.

Cone Calorimeter ISO 5660-1 Manufacturer in Maharashtra

FlareTest is a prominent Cone Calorimeter ISO 5660-1 Manufacturer in Maharashtra, known for delivering high-quality fire testing equipment. Our instruments meet ISO 5660-1 specifications and are built to measure key combustion parameters like heat release, ignition, and smoke output. Featuring robust construction, precision sensors, and user-friendly software, they ensure consistent and accurate testing results. Serving industrial labs and research centers across Maharashtra, FlareTest guarantees unmatched product quality and technical excellence.

Cone Calorimeter ISO 5660-1 Manufacturer in Haryana

FlareTest is a trusted Cone Calorimeter ISO 5660-1 Manufacturer in Haryana, producing advanced fire testing instruments for accurate and reliable performance. Our equipment evaluates heat release rate, smoke production, and combustion characteristics as per ISO 5660-1 requirements. Built with advanced features and sturdy construction, our cone calorimeters ensure dependable operation in both industrial and laboratory settings. FlareTest serves clients across Haryana with superior-quality, ISO-certified fire testing instruments designed for long-term efficiency.

Cone Calorimeter ISO 5660-1 Manufacturer in Punjab

FlareTest is a leading Cone Calorimeter ISO 5660-1 Manufacturer in Punjab, offering precision-engineered fire testing systems designed for ISO-standard performance. Our instruments deliver accurate analysis of heat release, ignition time, and smoke generation, ensuring complete compliance with ISO 5660-1 protocols. Crafted for high durability and consistent operation, they are ideal for industrial, research, and academic testing facilities across Punjab. FlareTest is known for reliability, precision, and continuous innovation in fire testing technology.

Cone Calorimeter ISO 5660-1 Manufacturer in Uttar Pradesh

FlareTest is a reputed Cone Calorimeter ISO 5660-1 Manufacturer in Uttar Pradesh, providing world-class fire testing instruments for laboratories and industries. Our cone calorimeters are designed to measure material combustion performance accurately in accordance with ISO 5660-1 standards. They offer high sensitivity, durability, and ease of use, making them perfect for advanced fire behavior testing. Trusted across Uttar Pradesh, FlareTest ensures exceptional product quality, consistent accuracy, and long-term reliability for all fire safety testing needs.

Cone Calorimeter ISO 5660-1 Manufacturer in Uttarakhand

FlareTest is a reliable Cone Calorimeter ISO 5660-1 Manufacturer in Uttarakhand, specializing in high-precision fire testing equipment. Our instruments provide accurate measurement of heat release rate, ignition time, and smoke generation in full compliance with ISO 5660-1 standards. Designed for research institutes and industrial laboratories, our cone calorimeters combine advanced technology with robust design for maximum reliability. Serving clients throughout Uttarakhand, FlareTest delivers high-performance, ISO-certified fire testing instruments trusted nationwide.

Cone calorimeter consists of the following primary components:

- Radiant Heater: A cone-shaped radiant electrical heater, consisting of an electrical heating rod wound into a truncated cone. It's rated at 5000W and capable of producing an irradiance of up to 100 kW/m² at the specimen's surface.

- Specimen Holder: A horizontal mounting facility for holding the specimen during testing.

- Irradiance Control: A PID temperature control system to regulate the cone's irradiance level.

- Load Cell: A load cell with a resolution of 0.01 g and an accuracy of ±0.3 g for measuring the mass loss rate of the specimen. It is positioned with proper thermal insulation to prevent heat interference.

- Exhaust Gas System: An exhaust system constructed from stainless steel for longevity. It includes an adjustable flow control system with a resolution of 0.1 g/s and a calibrated orifice plate flow meter to measure the volume flow rate of the combustion gases.

- Gas Sampling System: An apparatus for sampling the combustion gases, which includes a 3-stage filter system (with a filtration accuracy of up to 0.5 µm), a refrigerated cold trap, a diaphragm pump, and a moisture trap.

- Oxygen Analyzer: A paramagnetic oxygen analyzer with a measurement range of 0% to 25% by volume. Servomex, SIEMENS® or ABB® gas analyzers are optional.

- Carbon Monoxide and Dioxide Analyzers: NDIR (Non-Dispersive Infrared) analyzers for measuring carbon monoxide (range 0-1%) and carbon dioxide (range 0-10%). Servomex,SIEMENS® or ABB® gas analyzers are optional.

- Smoke Measurement System: A system for measuring smoke obscuration, which includes a helium-neon (He-Ne) laser, silicon photodiodes, and their mounting facilities.

- Calibration Flow Controller: A mass flow controller for methane gas, used for system calibration, with an accuracy of ±1.0% of full scale.

- Heat Flux Meter: A water-cooled heat flux meter (or radiometer) for calibrating the irradiance.

- Data Acquisition System: A system capable of recording data at a maximum rate of 50 records per second.

- Operating Software: Software that includes standard test protocols, sensor calibration, automated system calibration, real-time status monitoring, and report management.